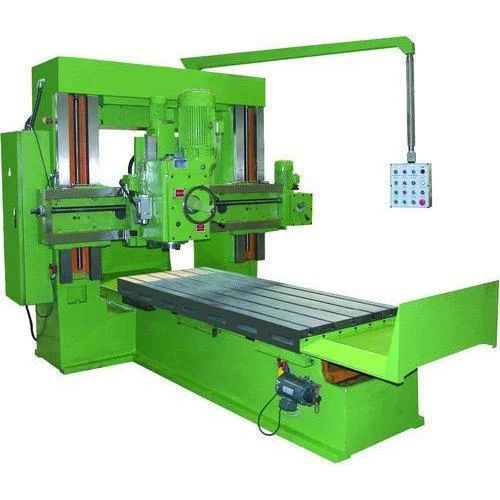

मà¥à¤à¤² à¤à¤¿à¤¯à¤° शà¥à¤ªà¤° मशà¥à¤¨

Price 150000 आईएनआर/ Unit

मà¥à¤à¤² à¤à¤¿à¤¯à¤° शà¥à¤ªà¤° मशà¥à¤¨ Specification

- फेज

- 3 Phase

- शेप

- Rectangular machine body, circular/pinion gear output

- व्यास

- Max. 12 inch gear diameter

- टॉर्क

- High torque output (exact value model dependent)

- प्रॉडक्ट टाइप

- Metal Gear Shaper Machine

- सामान्य उपयोग

- Gear shaping, cutting, and machining of metal gears

- मटेरियल

- टाइप करें

- क्षमता

- Up to 12 diameters (can vary as per model)

- वजन (किग्रा)

- Approx. 1200 - 1500 kg (model dependent)

- कम्प्यूटरीकृत

- ऑटोमेटिक

- टच स्क्रीन

- कंट्रोल सिस्टम

- सहनशीलता

- ±0.01 mm

- चित्रकारी

- वोल्टेज

- 415V / 380V 3 Phase (customizable as per region)

- आयाम (एल* डब्ल्यू* एच)

- Approx. 1800 x 1200 x 2200 mm

- फ़ीचर

- रंग

- Industrial green/blue/grey (as per manufacturer)

- Gear Cutting Speed

- Variable; up to 60 strokes/min

- Table Size

- Approx. 400 mm diameter

- Max. Table Load

- Up to 250 kg

- Module Capacity

- Up to 8 module

- Noise Level

- <75 dB(A)

- Lubrication System

- Automatic central lubrication

- Stroke Length

- Max. 150 mm

- Main Motor Power

- 2-3 HP

- Spindle Travel

- Up to 150 mm

- Coolant System

- Integral coolant pump and tank

मà¥à¤à¤² à¤à¤¿à¤¯à¤° शà¥à¤ªà¤° मशà¥à¤¨ Trade Information

- Minimum Order Quantity

- 10 Units

- भुगतान की शर्तें

- कैश एडवांस (CA)

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About मà¥à¤à¤² à¤à¤¿à¤¯à¤° शà¥à¤ªà¤° मशà¥à¤¨

Metal Gear Shaper Machine is perfect for making metal gear casings and other similar operations. It is a versatile machine that can be used for rolling, shaping and forming operations. These are high-speed, end-rounded and centreless shaping machines for the processing of precision gears. Metal Gear Shaper Machine offers many benefits such as longer life, improved surface finish, high accuracy and better productivity. It is a type of machine tool thatuses linear relative motion and to process internal gears and stepped gears. Provided machine is for dovetail sliders and cutting the teeth of internal gears.

Precision Gear Manufacturing

The Metal Gear Shaper Machine is engineered for high-accuracy gear shaping and machining. Equipped with a 0.01 mm tolerance and computerized numerical control, it ensures consistently precise outcomes on each cycle. Its rigid structure and superior materials contribute to minimum vibration and enhanced results, meeting the requirements of demanding industrial applications requiring reliability and quality.

Robust Construction & Heavy-Duty Performance

Featuring a body made from high-grade cast iron and steel parts, the machine guarantees durability and longevity, even under continuous heavy-duty use. It handles large workloadsup to 250 kg on the tableand accommodates gears up to 12 inches in diameter, making it suitable for producers and suppliers seeking robust output with minimal downtime and maintenance needs.

Flexible Operation & Energy-Efficient Design

This shaper provides variable gear cutting speeds (up to 60 strokes/min), semi-automatic controls via a hand wheel and lever, and user-friendly electrical interfaces. With an automatic lubrication system and integral coolant pump, the machine ensures optimal running conditions while minimizing noise below 75 dB(A). It is ideal for workshops prioritizing operational efficiency and workplace comfort.

FAQs of Metal Gear Shaper Machine:

Q: How does the Metal Gear Shaper Machine achieve high precision in gear shaping?

A: The machine utilizes advanced CNC technology, robust construction, and strict in-process quality control systems. With a tolerance of 0.01 mm and stable spindle travel, it ensures highly accurate shaping and cutting of metal gears every cycle.Q: What types of gears and materials can be machined with this gear shaper?

A: It is designed for shaping, cutting, and machining several gear profiles up to 12-inch diameter and 8 module capacity. The machine accommodates a variety of metals, including high-grade cast iron and steel, making it versatile for different industrial gear applications.Q: When is the Metal Gear Shaper Machine most beneficial for manufacturers?

A: This machine is highly beneficial when consistent, precise, and heavy-duty gear production is requiredespecially in industries demanding strict tolerances, high workload capacities, and repeatable quality across batches.Q: Where is this Metal Gear Shaper Machine typically installed and used?

A: Its primarily utilized in industrial gear manufacturing plants, automotive workshops, and machinery production facilitiesespecially by distributors, exporters, producers, and suppliers across India and international markets.Q: What is the process for operating the Metal Gear Shaper Machine?

A: Operation involves securing the workpiece on the 400 mm diameter table, setting the stroke and gear module parameters, and managing the shaping process via hand wheel, lever, and electrical controls. The integral lubrication and coolant systems ensure smooth and efficient operation throughout.Q: How does the machine enhance user safety and efficiency during operation?

A: The shaper is equipped with an automatic central lubrication system and maintains noise levels below 75 dB(A), which improves operator safety and comfort. Electrical controls and semi-automatic operation reduce manual errors and physical strain, boosting productivity and operational efficiency.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

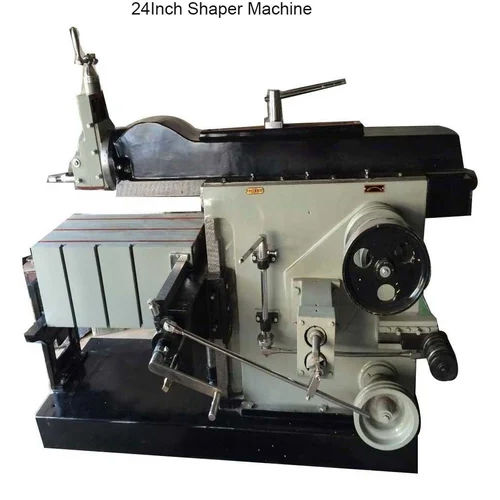

अधिक Products in Shaper Machine Category

औद्योगिक शेपर मशीन

मूल्य की इकाई : टुकड़ा/टुकड़ाs

माप की इकाई : टुकड़ा/टुकड़ाs

न्यूनतम आदेश मात्रा : 2

सामान्य उपयोग : Metal Cutting, Shaping and Planing

प्रॉडक्ट टाइप : Industrial Shaper Machine

वोल्टेज : 415 V

|

ARVIND ENTERPRISES

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें