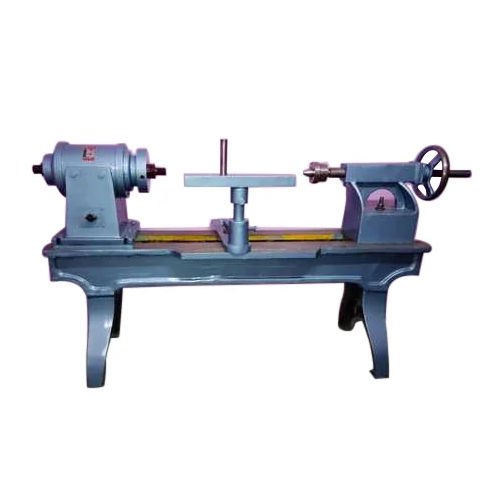

Heavy Duty Lathe Standard Machine

Price 170000 INR/ Unit

Heavy Duty Lathe Standard Machine Specification

- Product Type

- Heavy Duty Lathe Standard Machine

- Material

- Stainless Steel

- Cutting Thickness

- Up to 30 mm

- Cutting Speed

- 25 2000 mm/min

- CNC Or Not

- Normal

- Automatic Grade

- Semi Automatic

- Control System

- Frequency Speed Control

- Max. Swing Diameter

- 660 mm

- Voltage

- 415 V

- Weight (kg)

- 1800 kg

- Dimension (L*W*H)

- 3350 x 950 x 1390 mm

- Capacity

- High, suitable for robust metal processing

- Feature

- Heavy Duty Construction, Precision Bed, Hardened Guideways

- Color

- Standard Industrial Grey with Red Accents

- Tailstock Quill Travel

- 200 mm

- Lubrication System

- Automatic centralized lubrication

- Surface Finish

- Precision Scraped

- Threading Range

- Metric, Inch, Module, DP

- Chuck Size

- 250 mm (3-jaw scroll)

- Lead Screw Diameter

- 38 mm

- Coolant System

- Integrated

- Machine Base

- Rigid, one-piece cast iron

- Spindle Speed Range

- 40 1200 RPM

- Spindle Bore Diameter

- 80 mm

- Main Motor Power

- 5 HP

- Noise Level

- <80 dB

- Bed Width

- 400 mm

- Distance Between Centers

- 1500 mm

- Center Height

- 330 mm

- Tool Post Type

- 4-Way

Heavy Duty Lathe Standard Machine Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Heavy Duty Lathe Standard Machine

Heavy Duty Lathe Standard Machine is a very efficient machine which is used in many industries and also at home. It can be used by professionals as well as beginners to fulfil their requirements. Heavy Duty Lathe Standard Machine comes equipped with a full-width bed, that allows it to support larger workpieces, as well as a powerful motor that can handle heavy-duty workloads. It is to perform various operations such as cutting, sanding and drilling. The standard machine is to create an object with symmetry about an axis of rotation.

Precision Engineering for Robust Performance

Designed with precision scraped surfaces and hardened guideways, this lathe ensures smooth and accurate operations even under heavy workloads. Its rigid, one-piece cast iron base minimizes vibration, maximizing stability and longevity during intensive machining applications.

Advanced Features for Versatile Applications

The Heavy Duty Lathe Standard Machine offers a wide spindle speed range and cutting speeds of 25 2000 mm/min, capable of handling diverse materials and threading needs including metric, inch, module, and DP threads. Integrated coolant and automatic centralized lubrication systems maintain optimal operating conditions for extended use.

User-Friendly Controls & Efficient Operation

Equipped with frequency speed control and semi-automatic functionality, this lathe simplifies the machining process, facilitating precise and efficient operation. Its ergonomic design and standard industrial grey color with red accents add to both usability and professional aesthetic in any workshop.

FAQs of Heavy Duty Lathe Standard Machine:

Q: How does the automatic centralized lubrication system benefit lathe operation?

A: The automatic centralized lubrication system ensures continuous and consistent oiling of vital components, reducing friction, minimizing maintenance requirements, and extending the machines operational lifespan during demanding metal processing tasks.Q: What types of threading can be performed with this machine?

A: This lathe supports multiple threading standards including metric, inch, module, and DP, enabling versatile usage across a range of industrial projects and material types, and making it ideal for both standard and custom thread forms.Q: When should I use the integrated coolant system during machining?

A: The coolant system should be utilized during all metal cutting processes, especially when working at higher cutting speeds or when machining tougher materials, to reduce heat build-up, improve finish quality, and enhance tool life.Q: Where is this heavy duty lathe primarily manufactured and distributed?

A: The machine is designed, manufactured, and supplied in India, with distribution networks including exporters, producers, and suppliers who cater to industrial customers seeking reliable and high-capacity machining solutions.Q: What is the maximum cutting thickness and swing diameter for this model?

A: This lathe can handle cutting thicknesses of up to 30 mm and supports a maximum swing diameter of 660 mm, making it suitable for processing substantial and varied metal workpieces.Q: How is the spindle speed controlled and what range does it offer?

A: Spindle speed is managed via frequency speed control, allowing for precise adjustments between 40 to 1200 RPM, supporting both delicate and intensive machining requirements efficiently.Q: What are the main advantages of selecting a machine with a rigid, one-piece cast iron base?

A: A rigid, one-piece cast iron base provides outstanding vibration damping and structural stability, which are crucial for achieving high precision and durability during heavy duty operations, ensuring the machine remains dependable for rigorous workloads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

Heavy Duty Lathe Machine

Price 200000 INR / Unit

Minimum Order Quantity : 10 Units

Dimension (L*W*H) : 4200 x 1100 x 1450 mm

Product Type : Other, Heavy Duty Lathe Machine

Color : Gray & Blue

CNC Or Not : Normal

Spinning Lathe Machine

Price 130000 INR / Unit

Minimum Order Quantity : 10 Units

Dimension (L*W*H) : Approx. 2000 x 900 x 1400 mm

Product Type : Other, Spinning Lathe Machine

Color : Industrial Grey/Blue

CNC Or Not : Normal

Medium Duty Lathe Machine

Price 130000 INR / Unit

Minimum Order Quantity : 10 Units

Dimension (L*W*H) : 2000mm x 840mm x 1150mm

Product Type : Other, Medium Duty Lathe Machine

Color : Blue/Grey

CNC Or Not : Normal

Gear Head Lathe Machine

Dimension (L*W*H) : Approx. 2200 x 950 x 1320 mm

Product Type : Other, Gear Head Lathe Machine

Color : Standard Machine Grey with Red Accents

CNC Or Not : Other, Conventional (NonCNC)

|

ARVIND ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry