Most Popular Products

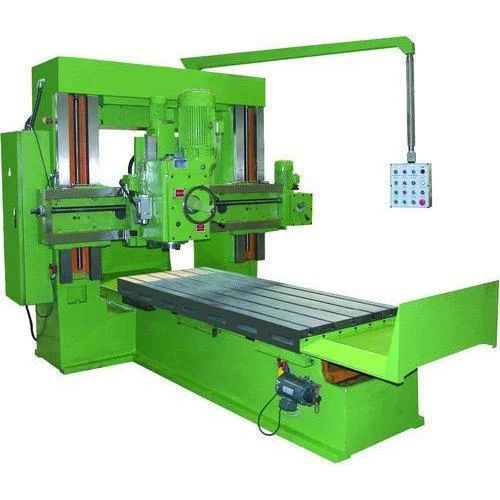

Industrial Planner Machine

Price 160000 INR/ Unit

MOQ : 10 Units

Industrial Planner Machine Specification

- Voltage

- 380 V

- Production Capacity

- 1.5 Ton/day

- Machine Type

- Planner

- Power Rating

- 5.5 kW

- Control System

- Digital Panel

- Noise Level

- <80 dB

- Operating Temperature

- 0-40C

- Connectivity Options

- Ethernet, USB

- Cooling System

- Air Cooled

- Accuracy

- 0.05 mm

- Frequency

- 50 Hz

- Motor Power

- 7.5 HP

- Model No

- IPM-2400

- Frame Type

- Steel Welded

- Features

- Heavy Duty Frame, High Precision, Robust Performance

- Drive

- Belt Drive

- Lubricating System

- Automatic

- Product Type

- Industrial Planner Machine

- Technology

- CNC

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Power

- 7.5 HP

- Pressure

- Adjustable up to 5 Tons

- Surface Treatment

- Painted

- Dimension (L*W*H)

- 2400 mm x 950 mm x 1200 mm

- Weight (kg)

- 1850

- Color

- Blue & White

- Usage & Applications

- Wood Planing, Surface Finishing, Shaping Timber

- Feeding Method

- Roller Feed

- Energy Consumption

- 4 kWh/hr

- Tool Change System

- Manual/Quick Change

- Minimum Board Thickness

- 4 mm

- Cutting Blade Material

- High Speed Steel (HSS)

- Dust Extraction Port

- Yes, 120 mm Diameter

- Maximum Board Width

- 600 mm

- Installation Type

- Floor Mounted

- Software Compatibility

- Windows, CNC Proprietary Software

- Safety Features

- Emergency Stop Button, Overload Protection

- Operating Humidity

- Up to 70%

- Display Type

- Digital Screen

- Cycle Time

- 45 sec/workpiece

Industrial Planner Machine Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Industrial Planner Machine

Industrial Planner Machine is a machine used to arrange, pack and move boxes or other items from one place to another. Industrial Planner Machine is used to cut and shape all kinds of materials such as wood, plastic and other soft materials. It can also be used to make holes in wood, plastics and other materials. It is a powerful, yet simple and easy-to-use system for planning production jobs.The planner machine carries two tool heads slides over the vertical faces of the machine housing. It ensures a good surface finishing and low maintenance.

Exceptional Precision and Efficiency

With a cutting accuracy of 0.05 mm and cycle times of 45 seconds per workpiece, the IPM-2400 sets a standard for high-precision wood shaping and planing. Heavy-duty construction and reliable air cooling maximize performance and minimize downtime, making it ideal for continuous industrial use.

Advanced Safety and User-Friendly Features

Operators are protected by multiple safety features including an emergency stop button and overload protection. The digital screen display, quick-install floor mounting, and easy-change blade system deliver streamlined operation, reducing setup and maintenance time.

Versatile Connectivity and Control

Seamlessly integrating with Ethernet and USB, the planner supports both Windows and proprietary CNC control software via its digital panel, ensuring adaptability in modern networked workspaces. Automatic lubrication and dust extraction ensure a clean, low-noise environment.

FAQs of Industrial Planner Machine:

Q: How does the IPM-2400 Industrial Planner Machine ensure operator safety during operation?

A: The machine features an emergency stop button for immediate shutdown, overload protection to prevent equipment damage, and a dust extraction port to maintain a clean working environment. These elements collectively protect operators and machinery.Q: What types of boards and wood materials can be processed with this planner machine?

A: The IPM-2400 accommodates wood boards with widths up to 600 mm and minimum thicknesses of 4 mm, making it suitable for various timber planing, surface finishing, and shaping applications across wood industries.Q: When is it necessary to change the cutting blades, and what system does the machine offer for this process?

A: Blade changes should be performed when surface quality declines or after extended use. The machine provides both manual and quick-change tool systems to facilitate fast and safe blade replacement, reducing downtime.Q: Where can this planner machine be installed within an industrial setting?

A: Designed for floor mounting, the IPM-2400 can be securely placed in factories, woodworking plants, or dedicated workshops, ensuring stability and easy maintenance access.Q: What software compatibility is offered with the IPM-2400 for machine control and data management?

A: The planner integrates with Windows operating systems and CNC proprietary software, enabling precise digital control and monitoring through its digital panel and connectivity options like Ethernet and USB.Q: How does the feeding process work on this planner machine?

A: Utilizing a roller feed system, boards are smoothly and consistently guided through the machine, ensuring uniform planing results and reducing manual intervention during processing.Q: What are the benefits of the dust extraction port featured on the IPM-2400?

A: The 120 mm diameter dust extraction port efficiently removes debris and fine dust from the work area, improving air quality, extending equipment life, and supporting a healthy work environment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

ARVIND ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry