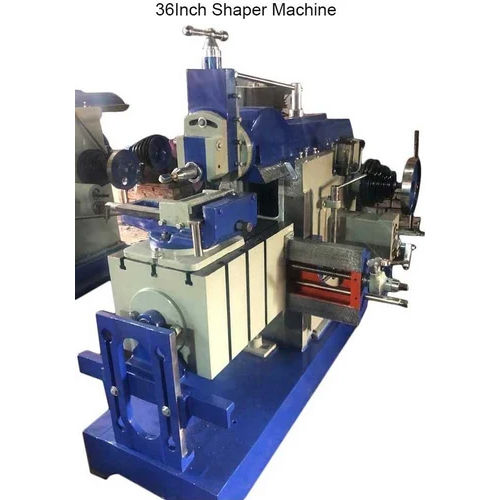

Industrial Gear Shaping Machine

Price 150000 INR/ Unit

Industrial Gear Shaping Machine Specification

- Shape

- Rectangular Base

- Phase

- Three Phase

- Torque

- 1800 Nm

- Diameter

- Max. Gear Diameter 600 mm

- Product Type

- Industrial Gear Shaping Machine

- General Use

- Gear Profile Cutting and Shaping

- Material

- High Grade Alloy Steel

- Type

- Vertical Gear Shaping

- Capacity

- Up to 5 Tons

- Weight (kg)

- Approx. 2200 kg

- Computerized

- Yes

- Automatic

- Semi Automatic

- Touch Screen

- No

- Control System

- PLC Control

- QC System

- Strict Quality Inspection

- Tolerance

- 0.02 mm

- Drawing

- Available on Request

- Voltage

- 380-415 V

- Dimension (L*W*H)

- 2400 x 1600 x 2400 mm

- Feature

- Heavy Duty, High Precision, Low Noise

- Color

- Industrial Grey & Blue

- Spindle Speed

- 40-400 rpm adjustable

- Lubrication System

- Centralized

- Chuck Size

- 250 mm

- Max. Gear Width

- 150 mm

- Main Motor Power

- 7.5 kW

- Cutting Stroke

- Up to 200 mm

- Noise Level

- <75 dB

- Application

- Automotive, Industrial Machinery, Transmission Gears

- Maximum Module

- 10 mm

- Table Diameter

- 650 mm

- Cooling System

- Water/Oil Cooling Available

Industrial Gear Shaping Machine Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Industrial Gear Shaping Machine

Industrial Gear Shaping Machine is designed in such a way that shapes the tooth profile or adds a profile of a gearbox. It is used in different industrial applications such as mechanical, automotive and electrical industries. Industrial Gear Shaping Machine is a device that creates high-quality gears that create accurate and efficient products with its powerful motor, precise cutting blades, and easy-to-use controls.The shaping machine is used forcutting spur and integral gear-pinion arrangements. It is one of the most versatile of all gear cutting operations to produce integral gear-pinion arrangements.

Product details

|

Color |

Green |

|

Country of Origin |

Made in India |

|

Material |

Mild Steel |

|

Type |

Gear Shaping Machine |

|

Automation Grade |

Automatic |

|

Usage/Application |

Industrial |

Robust Precision Engineering

Designed with a rectangular base and constructed from high-grade alloy steel, this gear shaping machine offers exceptional stability and durability. The advanced CNC-assisted operations ensure that each gear produced meets tight tolerance requirements, making it suitable for critical applications in automotive and industrial machinery.

Versatile Application and High Capacity

Capable of handling gears up to 600 mm in diameter and with a maximum width of 150 mm, this vertical gear shaping machine supports modules up to 10 mm. Its adjustable spindle speed and cutting stroke, partnered with a robust 7.5 kW motor, allow users to process a wide range of gear profiles effortlessly.

Advanced Control and User-Friendly Interface

Equipped with a PLC control system and featuring semi-automatic operating mode, this machine provides reliable performance and excellent repeatability. The centralized lubrication system and dual water/oil cooling ensure ease of maintenance and operational safety, even under rigorous production demands.

FAQs of Industrial Gear Shaping Machine:

Q: How does the centralized lubrication system benefit machine performance?

A: The centralized lubrication system ensures all critical moving parts receive consistent oiling, reducing wear and extending the machines operational life. This leads to lower maintenance costs and improved reliability during continuous gear shaping tasks.Q: What applications are ideal for this gear shaping machine?

A: This machine is ideally suited for manufacturing high-precision gears used in automotive, industrial machinery, and transmission systems. Its versatility allows it to accommodate a range of gear types and sizes, making it valuable for mass production and customized orders.Q: When should I use water versus oil cooling?

A: Water cooling is typically used for lighter operations or when rapid temperature reduction is needed. Oil cooling is better for heavy-duty, prolonged processes that generate significant heat, providing superior thermal stability and enhanced machine longevity.Q: Where is this gear shaping machine manufactured and supplied from?

A: The machine is manufactured in India, and is available through a network of distributors, exporters, manufacturers, and suppliers. It serves both domestic and international industrial sectors.Q: What is the process for adjusting the spindle speed and cutting stroke?

A: Spindle speed is adjustable between 40-400 rpm, and the cutting stroke can be set up to 200 mm via the control panel. Adjustments are managed through the semi-automatic PLC control system to match different gear shaping requirements precisely.Q: How does the machine ensure high precision in gear shaping?

A: With a tolerance of 0.02 mm, CNC-guided operations, and strict quality inspection protocols, the machine delivers gears with consistency and accuracy. The PLC control system also enhances repeatability, ensuring each piece meets specified standards.Q: What are the main benefits of using this gear shaping machine?

A: Key benefits include high production capacity (up to 5 tons), low noise operation (<75 dB), energy efficiency, superior durability, and the ability to handle a variety of gear sizes and profiles. Its advanced features increase productivity while maintaining quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Shaper Machine Category

Metal Gear Shaper Machine

Price 150000 INR / Unit

Minimum Order Quantity : 10 Units

General Use : Gear shaping, cutting, and machining of metal gears

Voltage : 415V / 380V 3 Phase (customizable as per region)

Product Type : Metal Gear Shaper Machine

Automatic : Other, Semi Automatic

Semi Automatic Shaper Machine

Price 5000 INR / Piece

Minimum Order Quantity : 2 Pieces

General Use : Metal Cutting, Shaping, and Slotting

Voltage : 415 V

Product Type : Semi Automatic Shaper Machine

Automatic : Other, Semi Automatic

12Inch Shaper Machine

Price 90000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Industrial

Voltage : 220 V Volt (v)

Product Type : 12Inch Shaper Machine

Automatic : Other, Semi Automatic

Manual Shaper Machine

Minimum Order Quantity : 1 Unit

General Use : Metal Shaping, Cutting, Slotting

Voltage : 220240V (for motorized feed only, if equipped)

Product Type : Manual Shaper Machine

Automatic : No

|

ARVIND ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry