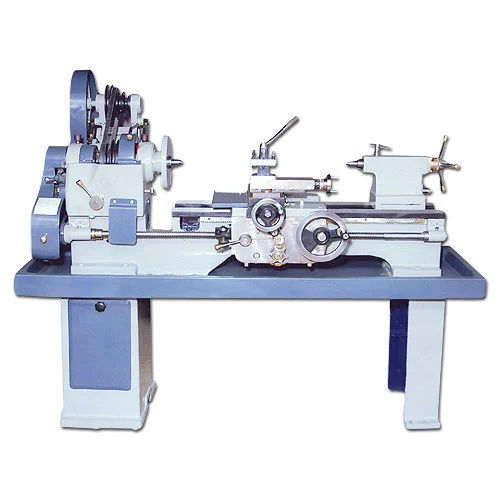

Spinning Lathe Machine

Price 130000 INR/ Unit

Spinning Lathe Machine Specification

- Product Type

- Spinning Lathe Machine

- Material

- Stainless Steel

- Cutting Thickness

- Up to 10 mm (depends on material and model)

- Cutting Speed

- Variable (typically 301800 RPM)

- CNC Or Not

- Normal

- Automatic Grade

- Semi Automatic

- Control System

- Frequency Speed Control

- Max. Swing Diameter

- Up to 1000 mm

- Voltage

- 415 V, 3 Phase, 50 Hz

- Weight (kg)

- Approx. 1800 kg

- Dimension (L*W*H)

- Approx. 2000 x 900 x 1400 mm

- Capacity

- Heavy-duty/Industrial Use

- Feature

- High precision, robust structure, variable speed drive

- Color

- Industrial Grey/Blue

- Main Motor Power

- 7.5 HP

- Chuck Size

- 500 mm

- Drive Type

- Belt and Gear driven

- Tailstock Quill Travel

- 150 mm

- Lubrication System

- Centralized Lubrication

- Application

- Metal Spinning, Shaping and Fabrication

- Bed Width

- 400 mm

- Spindle Bore

- 80 mm

- Number of Tool Posts

- 4-way

Spinning Lathe Machine Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Spinning Lathe Machine

A spinning Lathe Machine is used to produce precision quality threads on round, square or hexagonal rods and shafts. The Spinning Lathe Machine also has a live tool attachment. Spinning Lathe Machine creates your own roving, yarn, braids and more with this spinning lathe machine. It offers easy control for beginners and experienced spinners alike. It is one of the most used machine tools in the industry. Its very useful in shaping, grooving and finishing metallic parts.Provided machine is to create rounded metal parts from aerospace components. It is cheaper to produce than conventional tooling.

Product details

|

Product Type |

Gear Head Lathe Machine |

|

Country of Origin |

Made in India |

|

Bed Length |

7 Feet |

|

Machine Type |

All Geared Medium Duty Lathe Machine |

|

Max Swing Over Bed |

500 mm |

|

Number of Spindle Speeds |

5 |

Precision Metal Spinning & Shaping

Designed for optimal metal spinning and complex shaping, this lathe machine provides heavy-duty capabilities with a max swing diameter of 1000 mm. Its industrial-grade features, including robust structure and centralized lubrication, guarantee precise results and reduced maintenance effort, making it a top choice for fabrication professionals.

Variable Speed & Flexible Operations

Thanks to frequency speed control and a powerful 7.5 HP motor, this machine allows operators to select from a wide range of variable cutting speeds, adapting to diverse material requirements. The belt and gear-driven transmission ensures smooth operation, enhancing both productivity and efficiency.

Reliable Construction for Industrial Use

Made from premium stainless steel and weighing approximately 1800 kg, this lathe boasts a heavy-duty build suitable for continuous use in rigorous environments. Its centralized lubrication ensures optimum functioning of critical components, while the semi-automatic system streamlines the process for higher throughput.

FAQs of Spinning Lathe Machine:

Q: How does the frequency speed control benefit the operation of this spinning lathe machine?

A: The frequency speed control allows precise regulation of spindle speed between 30 to 1800 RPM, enabling adaptability to different materials or fabrication tasks. This optimizes the cutting performance and extends tool life.Q: What is the maximum cutting thickness and swing diameter capacity of the lathe?

A: This spinning lathe accommodates cutting thicknesses up to 10 mm, depending on material and model, and supports a maximum workpiece swing diameter of 1000 mm, making it suitable for large-scale projects.Q: When is it best to use the centralized lubrication system of the lathe?

A: The centralized lubrication system should be operated regularly during machine use and checked for fluid levels before each production shift. This proactive maintenance ensures smooth operation and minimizes wear on critical components.Q: Where can this spinning lathe machine be utilized effectively?

A: This machine is ideal for industrial manufacturing units, fabrication workshops, and metalworking facilities involved in metal spinning, shaping, and production of components from stainless steel or similar materials.Q: What is the process for changing the cutting speed on this lathe model?

A: Operators can adjust the cutting speed by using the frequency speed control, selecting the required RPM suitable for the workpiece material and the specific application, ensuring efficient performance and safety.Q: How does the semi-automatic grade of the lathe affect usage?

A: The semi-automatic grade allows operators to control key functions manually, benefiting from increased precision while reducing the manual effort involved, which is particularly valuable in complex or repetitive fabrication tasks.Q: What are the main benefits of installing this spinning lathe in your workshop?

A: This lathe provides robust construction, high precision, variable speed control, and the ability to handle large and thick metal workpieces, resulting in enhanced productivity, decreased downtime, and consistent high-quality outputs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

Heavy Duty Lathe Machine

Price 200000 INR / Unit

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Voltage : 380 V

Capacity : Up to 2 Ton

Color : Gray & Blue

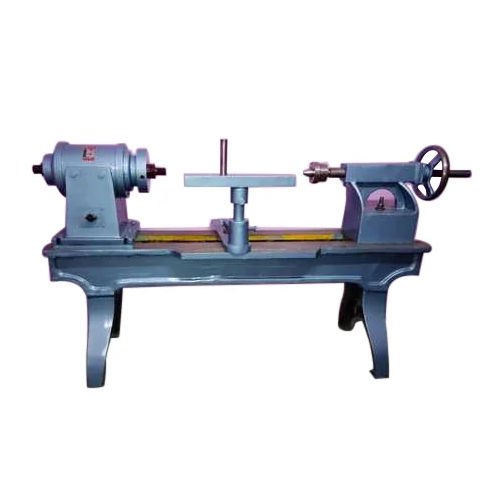

Medium Duty Lathe Machine

Price 130000 INR / Unit

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Voltage : 415V / 220V (Three Phase)

Capacity : Up to 1000 mm between centers

Color : Blue/Grey

Light Duty Lathe Machine

Minimum Order Quantity : 2 Pieces

Material : Cast Iron Body

Voltage : 220240 V

Capacity : Suitable for Small Workshops

Color : Industrial Green

Semi Automatic Lathe Machine

Material : Cast Iron, Mild Steel

Voltage : 415 V, 3 Phase

Capacity : Heavy Duty

Color : Blue and White

|

ARVIND ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry