Manual Shaper Machine

Manual Shaper Machine Specification

- Diameter

- Not applicable; uses ram movement for shaping

- Shape

- Rectangular Base, Moving Ram

- Torque

- Manual; not applicable for fixed gear

- Phase

- Single Phase (for motorized feed only)

- Product Type

- Manual Shaper Machine

- General Use

- Metal Shaping, Cutting, Slotting

- Material

- Cast Iron Body, Steel Components

- Type

- Mechanical, Horizontal

- Capacity

- Medium Duty

- Weight (kg)

- Approx. 600 kg

- Computerized

- No

- Automatic

- No

- Touch Screen

- No

- Control System

- Manual Lever Control

- Surface Treatment

- Painted Finish

- QC System

- Standard Quality Check

- Tolerance

- 0.02 mm

- Drawing

- Available on request

- Voltage

- 220-240V (for motorized feed only, if equipped)

- Dimension (L*W*H)

- Approx. 1650 x 900 x 1350 mm

- Feature

- Rigid construction, Smooth operation, User-friendly design

- Color

- Green/Grey (as per manufacturer)

- Longitudinal Table Travel

- 400 mm

- Working Table Size

- 300 x 320 mm

- Maintenance

- Periodic Lubrication Required

- Main Motor Power

- 1 HP (if fitted with power motor)

- Spindle Speed

- Variable by hand lever or motor

- Installation

- Floor Mounted

- Cross Slide Travel

- 200 mm

- Coolant System

- Optional

- Maximum Job Height

- 260 mm

- Accessories Included

- Vice, Tools, Allen Keys

- Number of Feeds

- Multiple, manually adjustable

- Ram Stroke Length

- 12 inches (300 mm)

Manual Shaper Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 7 Days

About Manual Shaper Machine

Primary Competitive Advantages and Specific Usage

The Manual Shaper Machine stands out for its user-friendly configuration, smooth operation, and rigid construction, making it a preferred choice among professionals. Its lavish tolerance of 0.02 mm ensures precision shaping, cutting, and slotting in repair shops, educational workshops, and small manufacturing units. Its capacity for medium-duty tasks and flexible manual adjustment provide a distinct advantage in repetitive and customized metalwork projects, delivering consistent results across a variety of application places.

Export Market, Domestic Reach & Sample Policy

The Manual Shaper Machine is widely handovered to international buyers across Asia and the Middle East, while maintaining a strong presence in Indias domestic market. Distributors, exporters, and manufacturers facilitate secure exchange and delivery upon confirmed purchase order. For importers or local businesses seeking product assurance, samples can be arranged before a full-scale exchange, ensuring transparency and satisfaction in every transaction.

FAQs of Manual Shaper Machine:

Q: How is the Manual Shaper Machine installed and maintained?

A: The machine is floor-mounted for stability and requires simple periodic lubrication to maintain optimal performance. Installation hardware and guidance are included, ensuring a seamless setup process.Q: What are the primary benefits of using a Manual Shaper Machine in workshops?

A: Its user-friendly design, smooth manual operation, and precise tolerance capabilities make it highly recommended for shaping, cutting, and slotting various metals, increasing efficiency in professional workshops.Q: When can I expect to receive a sample before placing a purchase order?

A: Samples are available upon request and can typically be exchanged after confirming initial interest, aiding informed decision-making before full procurement.Q: Where is the Manual Shaper Machine predominantly used?

A: The machine is ideal for repair facilities, educational institutions, and small manufacturing workshops requiring versatile shaping and cutting operations.Q: How does the variable spindle speed enhance the machines usage?

A: Variable spindle speed, adjusted manually by hand lever or motor, allows the operator to tailor the shaping process to specific job requirements, enhancing adaptability for different materials and finishes.Q: What process is followed for quality control of each machine?

A: Every unit undergoes a standard quality check system, ensuring conformity to specifications like rigid construction, painted finish, and operational tolerance before handover to buyers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Shaper Machine Category

Industrial Gear Shaping Machine

Price 150000 INR / Unit

Minimum Order Quantity : 10 Units

Voltage : 380415 V

General Use : Gear Profile Cutting and Shaping

Product Type : Industrial Gear Shaping Machine

Weight (kg) : Approx. 2200 kg

Industrial Shaper Machine

Minimum Order Quantity : 2 Pieces

Voltage : 415 V

General Use : Metal Cutting, Shaping and Planing

Product Type : Industrial Shaper Machine

Weight (kg) : Approx. 850 kg

18Inch Shaper Machine

Price 120000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220V Volt (v)

General Use : Industrial

Product Type : 18Inch Shaper Machine

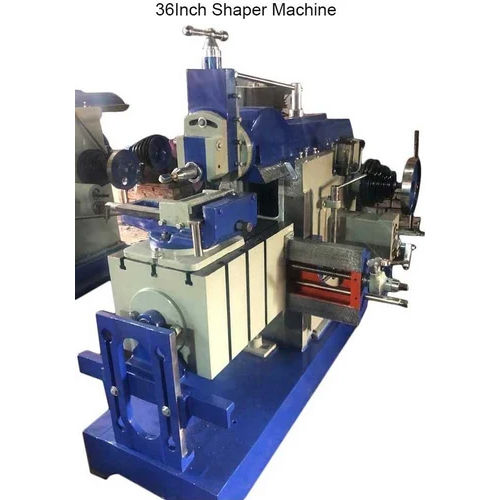

36Inch Shaper Machine

Price 345000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 240 Volt (v)

General Use : Industrial

Product Type : 36Inch Shaper Machine

Weight (kg) : 1600 kg Kilograms (kg)

|

ARVIND ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry